Sugaring has been a longstanding Bisbee’s Mill tradition in Chesterfield.

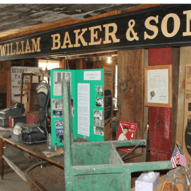

Elisha Bisbee enlarged the gristmill and built a mill pond and a 1400 foot canal to provide more drop and thus more power to the mill. By closing off the water in the evening and letting the pond fill, there was enough water to run the mill during the day. This worked well and the mill expanded to include a woodworking shop. In addition to grinding grain, the shop produced wooden product of the day including wagons and wagon wheels, tool handles, caskets and whip butts.

In 1919, the water wheel was replaced with a new state-of-the-art cast iron vertical axis water turbine to provide power. Electricity arrived a decade later and that state-of-the-art turbine was quickly abandoned in favor of electric power. As the mill was already configured to run off a central power source, a single 20 horsepower motor replaced the turbine and operated the existing belt driven equipment. However, with the arrival of electricity, water rights lost much of their value and business at the mill suffered.

The gristmill ceased operation around the time of electrification while the woodworking shop continued making specialty molding and tool handles before closing for good in 1960.

Today Bisbee’s Mill Museum continues to share its history and a glimpse into the history of the region.